Editorial Glass in Picture - October 6, 2025(link to original article) - Author: Marco Groothoff

First production line BENGglas® in Europe

Last September, BENGglas signed a Letter of Intent with LandVac to build a production site in Europe. LandVac, a subsidiary of LandGlass, has been in international sales of vacuum glass since 2016 and is considered one of the leaders in the industry. It is also the only producer of tempered titanium vacuum glass.

By soon producing this product in Europe as well, BENGglas can significantly reduce delivery times. 'That lays a solid foundation for further expansion in Europe,' says director Youri Creutzberg, 'and above all contributes to accelerating the energy transition.' To realize the plant before 2030, a good third-party partner is being sought. With his participation, BENGglas and LandVac expect to have the new production line operational within two to three years. Creutzberg: "We are only at the beginning. When we started BENGglas in 2019, there was hardly a market for vacuum glass in Europe. We had to build it completely from scratch. We did this by running radio campaigns, attending 10 to 15 trade fairs a year, being visible online and even deploying TV ads. Now, in 2025, the market looks completely different: demand has grown significantly and our dealer network has now expanded to 130 dealers worldwide.'

But more steps have been taken. In a short time, BENGglas has grown into a solid organization with a strong international presence. For example, the team has recently been strengthened with Arnoud Heijke, Régis Mutziak and Klaas de Weerd, who together bring more than 75 years of glass knowledge. This gives BENGglas a team of experienced professionals with broad expertise in glass and the glass market. High time to talk to Youri Creutzberg (DGA), Katja Creutzberg (Head of Marketing) and Arnoud Heijke (Senior Account Manager).

To start with the biggest news: how concrete is the intention to build in Europe?

Youri Creutzberg: 'It is more than concrete. The letter of intent has been signed and within two to three years we want to jointly realize a production site. LandVac provides the technology, we bring in the market knowledge, brand name, marketing and trade - in short, the square meters to fill the factory. We are also looking for a third party, preferably a large independent (insulating glass) manufacturer, who can contribute to the joint venture with its network and synergy. We are discussing this with several parties, but all options are still open.

Our goal is to produce BENG glass on European soil by 2028 at the earliest, and 2030 at the latest. You would think that you could easily place such a line in an existing factory, but that's not how it works. LandVac really wants to build the production line completely from scratch. That's indicative of their quality thinking: complete control over both production and the final product.'

How are you going to position BENG glass in Europe?

Youri Creutzberg: "Customers will soon have two choices. If they choose production in Europe, they benefit from faster delivery times and a more favorable carbon footprint. If they go for glass from China, the price is more competitive, but the delivery time is longer and the footprint slightly less favorable. Although I should add that the LandVac plant is already running entirely on hydroelectric and solar power, which significantly reduces the impact there. In the end, the choice revolves mainly around delivery time, carbon footprint and price.'

Where do you expect the production line to be located?

Youri Creutzberg: 'All options are still open, but Eastern Europe is the obvious choice. Countries like Poland, Hungary, the Czech Republic and Slovakia are among the possibilities. In these regions, energy and labor are more readily available and a strong industrial base is often already present. In addition, European subsidies may be available and the business climate is generally more favorable than in the Netherlands.'

How well are you guys doing?

Katja Creutzberg: "Well, pretty good. We have been named a Most Valuable Partner and deliver more in square meters than the United Kingdom and the United States combined. Since last year we have also been active in Scandinavia, Austria, Switzerland and Germany. There we were already present at trade fairs, but in 2026 we will strengthen our presence even further.

We are now focusing mainly on strengthening the quality perception of our product and educating the market. With our rebranding, the new website and attracting renowned partners such as Vandaglas, we have already made great strides. Our dealer network has also made a significant quality improvement. We want to involve that group more closely so that our quality continues to rise in all aspects.

Now it is up to us to continue. We have introduced the premium dealership and are going to offer our dealers even more knowledge and marketing support in the coming period. In doing so, they will benefit from our expertise and know-how. In this way we will not only make them stronger, but also true believers. You can safely say that we have matured as an organization.

Welcome Arnoud here at the table in Goirle. You gained a lot of glass experience at Fuldner, Pieterman, Cura and Ben Evers. What brought you to BENGglas?

Arnoud Heijke: 'I have been working in the glass world since 1997 and know the product from several sides: from the production machines, but also from production and trade. Since April 1, I get to add a new angle to that, which just goes to show how versatile glass is.

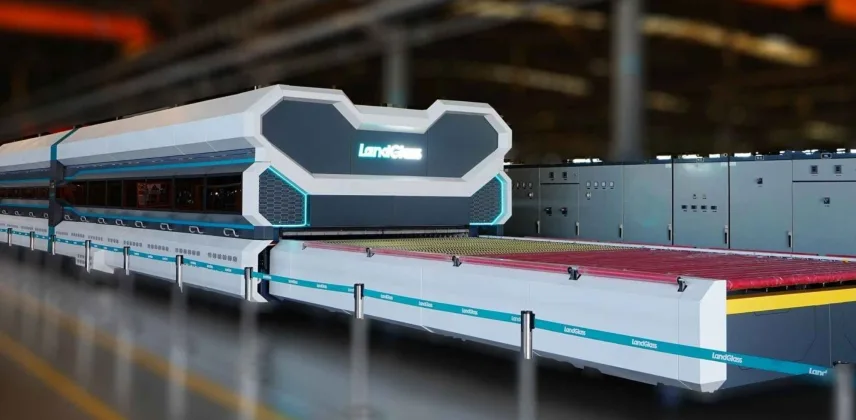

I was approached and took the step because I believe in the product. That belief only grew stronger when I visited the factories this spring. I was truly amazed. I already knew LandGlass from their (bending) tempering furnaces and their high quality. I won't name names, but large and renowned European glass companies swear by these technologically advanced furnaces.

If you can toughen a pane of glass measuring 3 by 2 meters and only 3 millimeters thick as flat and tight as steel, without anisotropy or airmarks, then you really have got something. LandGlass has been building complete plants and production lines for nearly thirty years - similar to what European machine producers like Hegla and LiSEC do.

When FINEO was introduced in 2019, LandVac was already operating in more than 50 countries. What also struck me: techies were walking around everywhere; even the CEO is an engineer. And you can see that in everything. It was downright impressive.

The production of BENG glass is different from that of FINEO, which basically reverses traditional insulating glass production: first vacuuming a large sheet of glass and cutting the panes from it. How is BENG glass made?

Arnoud Heijke: "Our production is much more like custom-made, like insulation glass. First the glass edges are primed and coated with a thin layer of titanium. Then the panes are toughened. In the vacuum chamber, the glass panes are brought together and a computer-controlled process places the spacers and absorption strip.

Then the edges are sealed under vacuum using the induction welding principle. The use of titanium is special: this very hard and light metal does not react with gases or water under normal conditions. Only above 300 °C does it absorb oxygen, hydrogen and nitrogen. Thanks both to this material and the specific production process, the edge connection of our vacuum glass is 40% stronger than connections with other metals. Because the edge is so crucial for quality, we can also achieve a higher degree of vacuum.

The spacers - called pillars - are made of stainless steel and, like the absorption strip, are titanium-coated. To prevent shifting, the glass also contains a subtle rill. Finally, each pane is passed through a heater to activate the absorption strip. In this way, LandVac tests each pane separately for function and insulation value'.

What about the use of heavy metals?

Youri Creutzberg: 'We fully comply with all regulations regarding the use of harmful substances. The edge connection has been tested according to European Directive 2011/65/EU, better known as RoHS 2.0. That test - the results of which can also be found on our website - shows that no hazardous substances such as lead, mercury or cadmium were found.'

What product developments can we still expect?

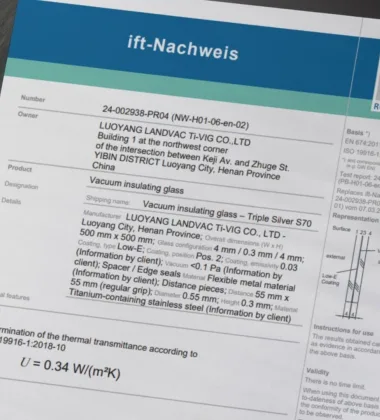

Katja Creutzberg: 'There are many projects underway at the moment. We now have various European test reports from institutes such as TÜV and ift Rosenheim, and we are included in GlassAdvisor. There is no European harmonized standard yet for vacuum glass, but we expect to be fully prepared as soon as a CE requirement is introduced. This puts us ahead of the regulations and allows us to cash in on our position as soon as the standardization is in place.

In early October at Pyroguard in Seingbouse, we successfully tested a 15-millimeter product in glass types EW30 and EW60. We cannot say anything about the details yet, but the first results are very positive. Incidentally, our product can already be used for fireproofing - with test reports to back it up - but in a hybrid composition.

We are also working with DUCO and Aluplast, further developing BENGglas SUN. This glass, with integrated PV, is now also available in an extra clear version. With a Ug of 0.5 W/m²K and in laminated form, it is also impact-resistant and can be walked on occasionally. So it is not a vision of the future, but already an applied product. For the longer term we are thinking of curved vacuum glass, an even thinner edge and the integration of dynamic electrochromic glass'.

Arnoud Heijke adds, "On the project side, more and more great references are coming in. For example, for the transformation of the former KPN headquarters in The Hague - a project of the Government Buildings Agency - we supplied BENGglas Hybrid. This allowed the existing aluminum window frames to be retained. With 1,900 square meters, as far as I know, this is the largest project with hybrid vacuum glass outside of China.

The business case included triple glass as an alternative, but because the window frames could remain, we came out of the equation better. With a Ug lower than 0.4 W/m²K. We delivered assemblies from 24 to 28 millimeters thick: insulating, burglar-resistant and fire-resistant. Almost everything came from China, except the fire-resistant glazing - it was assembled in France at Pyroguard. And why not? It works, as long as you supervise it properly.'

The "normal" insulation value of vacuum glass is 0.7, but BENG glass sits at 0.4. This is due to the greater distance between the spacers: conductive or not, they still form thermal bridges. Only thanks to tempered glass is that greater distance possible. But doesn't toughened glass break easily, and isn't it burglar-resistant according to NEN5096?

Youri Creutzberg: 'That is true, but that standard only applies to new buildings, not to replacement projects. When burglar resistance is required or desired, we apply laminated glass. That is already possible with EVA and PVB, and soon even with SGP, with which we can achieve even higher performance.'