Advantages of vacuum glass

The best insulation value on the market: U = 0.35

For quiet living (-36 dB)

Fits into existing window frames

Lets in 15% more natural light than triple glazing

15 year warranty with an expected lifespan of up to 50 years

Fully tempered: 5x stronger, injury-proof without the risk of thermal breakage

Better energy label, higher home value, the same appearance

Up to 65.50 euros per m² subsidy on vacuum glass

Vacuum glass - the best insulation value for every frame

With the introduction of vacuum glass, a revolutionary step has been taken in the field of (glass) insulation. Vacuum glass is extremely thin insulating glass in which two glass plates are separated by a vacuum space. Unlike traditional insulating glass, which uses inert gas or air between them, the conduction of a vacuum is minimal. As a result, vacuum glass achieves extremely good sound and heat insulation values, while the frames and appearance of your building are preserved - unlike HR++ or triple glazing. Less material, and therefore also a sustainable choice in that respect.

History of vacuum glass

Vacuum glass - also known as Bengglas® - was first described in a German patent from 1913, but it took until the mid -20th century before the technology was actually applied. The first commercial product was eventually launched in 1996 and was also available directly on the Dutch market from that moment.

A smart investment

Vacuum glass plays an increasingly important role in the energy transition we are in. For the simple reason that glass is a major part of the building envelope of homes and commercial properties, and therefore has a major impact on energy consumption. Replacing non- or poorly insulating glass with vacuum glass is an effective way to save energy costs, improve the energy label and even achieve the BENG standard.

✓ Save on new material (frames and hinges and locks)

✓ Take advantage of the best glass insulation value and an improved energy label

✓ The insulating glass with the longest lifespan

✓ Vacuum glass from Bengglas® is standard hardened

Sustainable future with BENGglas®

✓ 30 years of experience in glass

vacuum glass from Bengglas® has been available on the Dutch market since 2020 and has its origins in Giga glass, an international glass wholesaler with no less than 30 years of experience.

✓ Vacuum glass

has developed the future Bengglas® with the intention of gaining rapid raping. Important pillars are the product awareness of vacuum glass and fair prices. With that we make vacuum glass accessible to anyone who strives for a sustainable future.

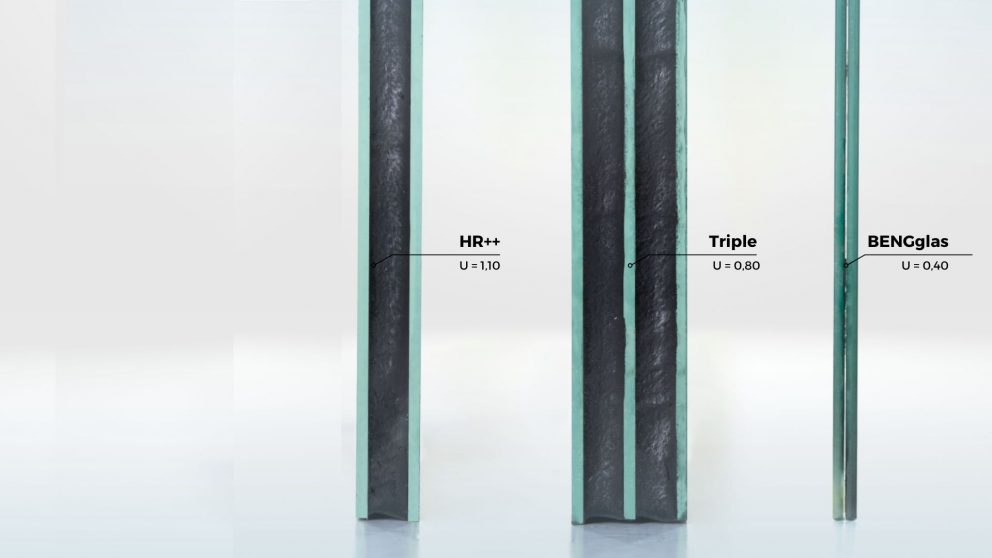

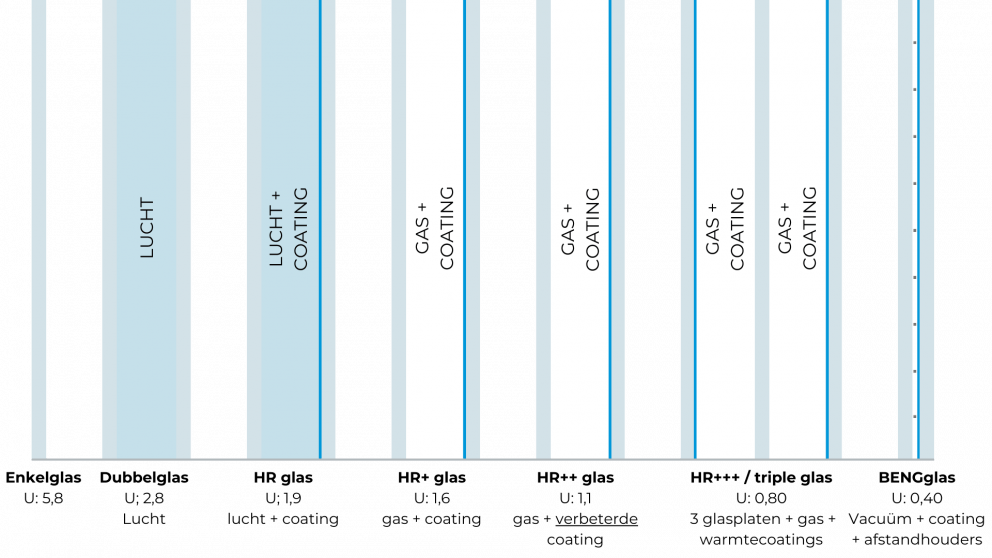

U-value vacuum glass

The insulation value, expressed in a U-value for glass, shows the heat drug coefficient (heat loss) of a glass construction. So the lower the U-value, the better the window insulates. The U-value of vacuum glass (Bengglas®) with double coating. That means that this vacuum glass isolates twice as well than the much thicker HR +++/triple glass (0.80) and almost three times as good than HR ++ (1.10).

Vacuum glass lifespan

The lifespan of vacuum glass is at least 25 years, while retaining its extremely good insulation value. But with a bit of luck, your vacuum glass has a lifespan of no less than 50 years. While traditional insulating glass has a lifespan of approximately 20 to 40 years, the insulation value can also decrease due to leakage in the frame. We hear you thinking: Vacuum glass has only been on the market since 1996, so how do you know what its lifespan is? Through reliable laboratory tests. In the lab we can simulate weather and light conditions that correspond to a period of 50 years. This allows us to guarantee a long lifespan.

Appearance is preserved

BENGglas® even fits in window frames that currently contain some panes. This allows the authentic window frames and the appearance of the building to be preserved. For this reason, vacuum glass is now used in many monuments during renovations and restorations.

Even 'monument vacuum glass' possible

Making a monument more sustainable and precision is made. Because it is very important that the authentic appearance is retained. Some monumental buildings also include 'wavy' windows with that characteristic picture. No problem for vacuum glass from Bengglas®. By laying the vacuum glass with a monumental window (Goethe of Monumentenglas), a window is created that has both that authentic look and is insulated to the maximum. So the best of two worlds.

Are you going for an authentic look? Then choose the extra clear vacuum glass from BENGglas Extra Clear . This glass is extra clear and has the appearance of single glass.

Warranty & costs vacuum glass

Guarantee

Due to the longer lifespan, the warranty on Bengglas® is not the usual 10, but 15 years. The warranty concerns the re -supply of the vacuum glass, not any costs for placement

Costs

What do vacuum glass solutions cost? We are often asked that question, very logical. The short answer: the price of vacuum glass is higher than that of traditional insulating glass. But that is not a fair cost estimate. Because for a good price comparison you have to take all kinds of things into account. Such as the savings on new window frames and hinges and locks (often necessary with traditional glass), but also the available subsidies on vacuum glass, not to mention the lower energy costs and improvement of your energy label.

Our BENGglas® dealers can calculate a fair and complete vacuum glass price for you, in which all aspects are taken into account.

Request a quote immediately!

Request a quote and we will forward it to a dealer in your area, that's easy. If you have any questions, you can also contact us, we are ready to help you.

Reference projects BENGglas®

- ABOUT VACUUM GLASS

Vacuum glass is an extremely thin type of insulating glass in which two glass plates of at least 4 millimeters are separated by a vacuum cavity of at least 0.15 millimeters. This means that the total thickness of the glass package amounts to 8.15 mm. Despite this small thickness, U-values of no less than 0.35 W/m2K are achieved.

To distribute the pressure of the glass over the glass surface and prevent the two glass plates from touching each other, micro spacers are evenly distributed over the entire glass surface. These spacers are located every 40 to 60 mm (depending on the type) and are barely visible from 2-3 meters.

Because the glass plates are hermetically sealed, there is minimal heat or sound transmission and optimal insulation can be provided.

Some important features and benefits of vacuum glass are:

- Excellent thermal insulation: The absence of air or gas between the layers of glass significantly reduces heat conduction, making vacuum glass one of the most thermally efficient glass products. It keeps heat in in winter and heat out in summer, reducing energy consumption for heating and cooling.

- Thin and lightweight: Vacuum glass is thinner and lighter than HR++ or triple glass. While HR++ and triple glass are often too thick for older frames, vacuum glass almost always fits in the existing frames. This saves on new window frames, but also on the purchase of new hinges and locks, labor and time. The installation of the glass also takes much less time because it is less labor intensive due to the light weight of the glass compared to, for example, triple glazing.

- Improved Sound Insulation: Due to its dense construction, vacuum glass can also reduce sound transmission, resulting in a quieter indoor environment. In this way, BENGglas® reduces 36 dB. In a layered version this increases to 39 dB.

- Condensation control: As with other insulating glass, vacuum glass helps prevent condensation on the inside of the window. Condensation can always form on the outside, but this is a sign of good insulation.

- Energy efficiency: The use of BENGglas® contributes to reduced energy consumption and lower energy costs. BENGglas® also reduces the energy requirement of a home. This allows savings in the number of solar panels or the strength of the heat pump.

The origins of vacuum glass date back to a 1913 German patent, but it took until the mid-20th century for this innovative technology to become a reality. The debut on the commercial market did not take place until 1996, when the product first became available in the Netherlands.

BENGglas® has entered the Dutch market since 2020, and its roots can be traced back to Giga-Glas! BV, an international glass wholesaler with three decades of experience. BENGglas® vacuum glass has now acquired a prominent position in the insulating glass market. The organization is actively committed to accelerating the energy transition by increasing product awareness and charging fair prices.

The lifespan of vacuum glass has been tested and appears to be at least 25 years, while retaining its insulation value. The glass is expected to last up to 50 years. The warranty for BENGglas® is 15 years compared to what is common (10 years).

A leak in HR ++ or triple insulating glass is created because the frame that holds the glass plates together is not airtight. This allows the noble gas to escape and condensation over time. The edges of vacuum glass, on the other hand, have merged together, leaving the vacuum intact. This retains vacuum glass its insulation value. Unlike HR ++ or Triple Glas, there is therefore no relegation in vacuum glass and the U-value remains at 0.35 for Bengglas Max type. Even if the vacuum glass is placed in a slope, there is no relapse of the insulation value.

Aged insulating glass has a high U-value (insulation value), which could cause condensation moisture to form on the inside of the glass. Because the U-value has greatly improved, condensation will only occur on the outside during the 'condensation' season. This does not have a disturbing effect and does not damage the panel.

To prevent the glass plates from being pressed together by the vacuum, microscopic spacers in vacuum glass are required. BENGglas® has the smallest and fewest spacers of all brands and available types of vacuum insulating glass.

When you choose vacuum glass, you will always have to deal with absorption points or absorption strips. The vacuum cap can sometimes be avoided by means of special production techniques.

Where the absorption points are intended to extract moisture extract air If the vacuum caps are missing, the air is extracted from the corners of the vacuum glass.

The combination of both creates a vacuum so that no conduction can occur between them. Without conduction, heat remains inside and cold outside (or vice versa in summer), which ensures the best insulation value.

The number of absorption strips and points can increase as the surface area of the window increases. Therefore, always consult the technical drawings of the relevant model before purchasing. It is important that these strips are neatly concealed behind the glazing beads/putty. Calculate carefully whether you have enough space for this.

Vacuum glass insulates better, but also retains its U-value (insulation value) after 25 to 50 years.

Unlike other types of insulating glass, vacuum glass is airless, so no conduction can occur. This keeps heat inside and cold outside (and vice versa in the summer).

The conductivity is a lot greater with other types of insulating glass as they are processed using air or noble gas. These gases escape through the frame over time, causing other insulating glass (for example: HR ++ or Triple glass / HR +++) to lose its original insulation value over the years.

There is still no harmonized standard requiring CE marking that includes vacuum glass. This is also not expected in the short term. Other brands of vacuum glass cannot therefore have a CE marking.

Vacuum glass consists of two slender glass plates of only 4 mm thick each. The glass plates are separated by a high vacuum space of 0.30 mm. This brings the total thickness of vacuum glass to just 8.3 mm ..

The vacuum glass from Bengglas® is available in the following glass thicknesses: 8.3- 10.3- 12.3- 16.3 mm. Ticking or laying is possible.

There is no additional charge between panes of 8 or 10 mm glass thickness. A small surcharge applies to windows from 12 mm.

To make a fair price comparison between BENGglas® and other insulating glass, you must make an overall cost calculation, including taking into account any replacement of window frames or hinges and locks, subsidies and what the investment means for your energy label. When you switch from single glazing to BENGglas®, for example, you do not have to replace your window frames, which can save costs. In addition, your energy label will increase more if you choose BENGglas® than if you switch to HR++ glass, for example. Our BENGglas® dealers are able to make a fair cost comparison for you, including taking such aspects into account.

IS the subsidy is available on Bengglas®. To replace your glass in the Netherlands, it is € 25 per m². If you also replace your frames, you are eligible for a subsidy of € 65.50 per m². Business customers are eligible for the energy investment allowance (EIA); This can amount to € 300 per m². These subsidy amounts double if you take a 2nd measure (or more). Source : www.rvo.nl. In Belgium (Flanders) this is € 16 per m² for replacing the glass (excl. Frames). You can request the subsidy via the online counter on Vlaanderen.be.