Telegraph | Feb. 19, 2024

The cap used to vacuum the glass sheets was sometimes still visible, and there were also pits in them. Yet four years ago, with the energy transition in mind, entrepreneurial Creutzberg family immediately saw potential in a new type of insulating glass from China.

"This product is really in development, so it was quite a big gamble to bring it to the Netherlands," says Youri Creutzberg, director of vacuum glass supplier BENGglas. Creutzberg is a scion of the 30-year-old family business Giga-Glas, which focuses on safety glass, including glass sheets for bus shelters, bus shelters, balustrades, but also for the parapets of office buildings, for example. "Insulating glass for homes, which we are now focusing on with BENG glass, is really a whole other world," Creutzberg said. To keep things separate, therefore, a separate limited liability company was established.

Energy neutral

The name BENG glass is a nod to the requirements for Nearly Energy Neutral Buildings (BENG), which permit applications for all new construction must meet since 2021. "The glass we supply, with a U-value (the insulation value, ed.) of 0.4, is excellent for designing to that standard," Creutzberg says. "Unlike the well-known insulating glass where there is space between the glass sheets, with this glass two sheets are vacuum sucked, making it much thinner than comparable products and it insulates even better," he explains. "HR++ glass, which is most commonly used in our country, has a U-value between 1.1 and 1.2."

Still, developers of new construction projects are not - yet - the largest consumer of vacuum glass. Especially for the renovation market, this type of glass is a no brainer, in Creutzberg's words. "It is so thin that it can be installed in existing window frames, allowing monuments and historic buildings to be insulated without losing their authentic appearance. It is therefore ideal for the European market."

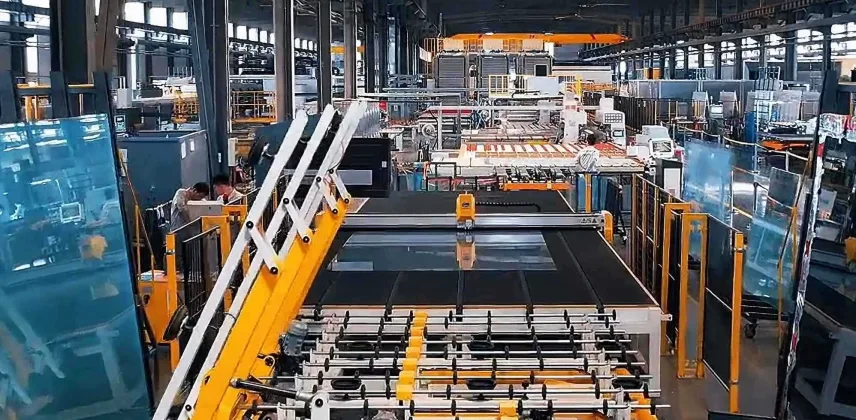

Although a solid company now stands, supplying the vacuum glass exclusively within the Benelux and also having dealers in Germany and Great Britain, the road to it has not always been easy. After extensive market research in China, the family found several suppliers from which they now source the glass. "Toughened vacuum glass is already a lot better known there than here in Europe, so developments are fast. The production is just gigantically difficult so there are not very many factories that can do this in China either."

Objections

Conquering that market is now going steadily, but especially in the beginning it was hard work to get a foothold. "This glass is a lot pricier than what the market is used to here, so we ran into a lot of objections, especially in the beginning," Creutzberg said. "We had a lot to counter that, such as the fact that this glass lasts much longer, the insulation value provides significantly higher energy savings, and it saves on replacing the window frames. By now we can really see that the market is warming up. In that respect, our timing is also good. We are 100% on board with the energy transition."

Doing business in China is not always easy either, Creutzberg acknowledges. But the experience the family already gained in that country with Giga-Glas did ensure that they did not encounter any major unforeseen surprises in recent years. "We know from experience, for example, that it is important to go that way regularly. If you discuss things in person, you really do get more done."

Local factory

Trust is really the key word, the entrepreneur emphasizes. "In China it is very normal to do everything on a down payment, which is of course a big risk especially for a starting company. Because with Giga-Glas we were already used to working with Chinese parties, it was a bit easier to take that risk than if you have never done business in that country before," he thinks. "And fortunately, as you do business with each other for longer, they also become more flexible about it. Once you have gained their trust, it becomes easier to make agreements."

That built trust has now also led to agreements on the production of the vacuum glass on European soil. "We were able to secure an option on our own machine in our agreement," Creutzberg says. "As such, importing the glass - 90% of which we have it come here by train - is going absolutely fine right now, but in the long run we do want to set up our own production line. We really believe that this product is the future, and with that ultimately fits a local factory, so that we minimize our carbon footprint."

Source: Telegraph

Date: Feb. 19, 2024

Go to the original article