Why standard EN 674 is the right choice for vacuum glass (and why EN 673 is not)

When choosing high-efficiency vacuum glass, it is important to understand which standard reflects true performance. The widely used standard EN 673 is designed for standard insulation glass with gas filling, but does not provide a reliable basis for vacuum glass. In contrast, standard EN 674 measures actual performance of vacuum glass and is therefore much more suitable.

In this article, we explain in simple language which standard counts, why it does, and how you, the consumer, can be sure you are getting honest information.

EN 673 vs. EN 674: what's the difference?

Many U-values in the glass world are calculated (not measured) according to the EN 673 standard. That works fine for standard insulating glass with a cavity filled with gas. But vacuum glass works very differently. Therefore, EN 673 is not reliable for this type of glass. So on the test reports, always check the standard used in the U-value report. We briefly explain below what exactly is different and why it matters.

Why EN 673 is not right for vacuum glass

EN 673 takes into account things that do not apply to vacuum glass, such as:

- a gas-filled cavity instead of a vacuum cavity.

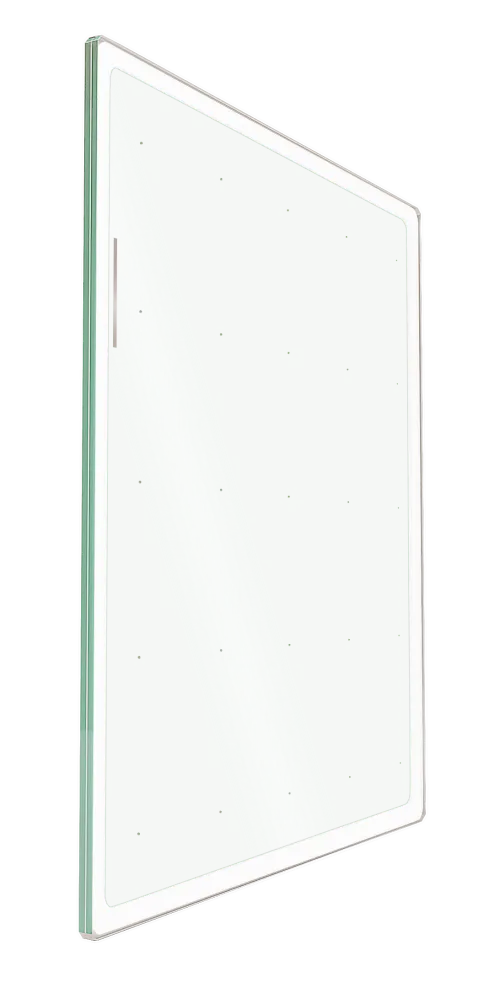

- a standard edge seal with a traditional spacer. Vacuum glass uses a rigid, fully sealed edge seal instead of a traditional spacer. As a result, the edge behaves differently and causes additional heat loss.

- To prevent the two panes of vacuum glass from breaking due to air pressure, vacuum glass uses microscopic spacers between the two panes of glass. These spacers conduct heat and therefore have a great impact on the insulation value. You don't have these internal spacers in standard insulating glass.

The heat loss that occurs through the spacers and the edge seal are therefore not taken into account in the standard of EN 673. As a result, EN 673 often gives too optimistic U-values for vacuum glass.

Why EN 674 is the right standard

Standard EN 674 uses a so-called heat-flow meter consisting of physical measurements of heat transmission through glass. It includes important aspects for vacuum glass in the calculation, such as the vacuum space, internal spacers and edge sealing.

This also includes the thermal bridges that you only have with vacuum glass. The result is a realistic and reliable U-value of the glass you get in your home.

In short:

- EN 673 calculates, EN 674 measures.

- EN 673 leaves out important aspects for vacuum glass that affect the insulation value , while EN 674 does take these important aspects into account.

In other words, EN 674 is a lot fairer than EN 673 for vacuum glass.

How BENGglas deals with this

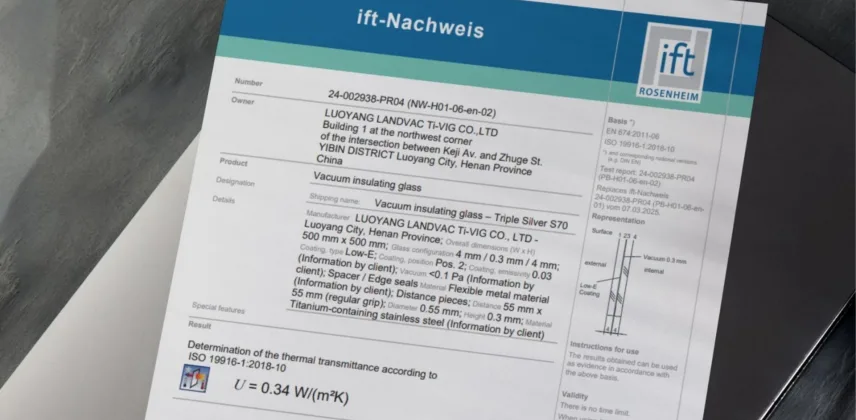

At BENGglas®, we believe it is important that you know exactly what you are buying. Therefore, all our vacuum glass is tested to the appropriate standard:

- EN674:2011-06 or ISO 19916-1:2018-10

These standards perfectly match vacuum glass and give an honest picture of the true insulation value.

So we never use EN 673 with vacuum glass, because this standard wrongly makes the product look better than it is. So we avoid disappointment and you get the performance you should expect. Check out all our documentation in the link below!

Why this is important for your home

A reliable U-value is essential when investing in glass that will last for decades. It determines:

- how much heat you retain

- How much energy you save

- how much comfort you experience, especially in winter

- whether you meet requirements of renovations or improvement projects

If the U-value is presented more beautifully than in reality, it can lead to disappointing results. That is why it is so important that the value is really correct.

How to compare vacuum glass honestly

When comparing different providers, pay attention to these four questions:

- Is the U-value measured according to EN 674 or ISO 19916-1?

- Has the real product been tested, not just a theoretical model?

- Are the micropillars and edge seal included in the measurement?

- Does the tested glass construction match what you receive?

If the answer to any of these questions is "no," chances are you're comparing apples to oranges.

What you can expect from BENGglas®.

With BENGglas® you get vacuum glass that:

- Has truly been tested to the correct standard

- has a U-value that is correct

- meets the highest standards

- provides more comfort and lower energy costs

No fancy talk, but real performance.