What is vacuum glass?

Vacuum glass is a type of double glazing, but instead of a cavity filled with noble gas, there is a complete vacuum between the glass panes. As a result, heat and sound conduction is minimal, and with only 8.3 mm glass, you achieve an insulation value that is up to three times better than HR++ and twice better than triple glazing. BENG's vacuum glass:

- insulates 3× better than HR++ and 2× better than triple glass

- fits into existing window frames, saving on new material

- lasts 2× longer - up to 50 years compared to 30 years for regular insulating glass

- attenuates noise from 36 dB (vs. 33 dB for triple glazing)

- lets 15% more daylight through than triple glazing

- consists of 30% less material than triple glazing

- remains stable at an angle of inclination, where regular glass drops up to 60%

- is toughened as standard - with no chance of thermal breakage (injury safe)

- leads directly to higher home value - through improved energy label

- Receives up to 46 euro p/m² subsidy - for national monuments

Differences at a glance

| BENGglas | Double glazing | Triple glazing | |

|---|---|---|---|

|

U-value (W/m²K) |

>0,35 | 1,10 | 0,70 |

|

Thickness from (mm) |

6,7 | 21 | 38 |

| Fits existing window frames | Yes | Sometimes | No |

| Tempered |

Standard EN3569 Except for BENGglas 6,7 mm (half tempered) |

Optional | Optional |

|

Light Transmission (LTA in %) |

> 83 | 80 | 65 |

|

Solar Heat Gain (G-value) |

>0,33 | 0,76 | 0,52 |

|

Sound Insulation Rw (C;Ctr) dB |

36 (–2; –3) to 41 (-2;-6) for BENGglas Hybrid |

31 (-1;-4) | 33 (-2;-6) |

| Insulation degradation at horizontal tilt (%) | 0 | 60 | 40 |

| Expected lifespan (years) | 50 | 20 - 25 | 30 |

| U-value degradation over time? | No | Yes | Yes |

| BENGglas Extra clear | BENGglas Single Coated | BENGglas Double Coated | BENGglas Triple Coated | BENGglas Monu | BENGglas Monu Restover | |

|---|---|---|---|---|---|---|

|

U-value (W/m²K) |

0,50 | 0,40 - 0,50 | 0,40 | 0,35 | 0,50 | 0,50 |

| Thickness from (mm) | 8,3 | 6,7 | 8,3 | 8,3 | 8,3 | 13,06 |

| Light Transmission (LTA %) | 83 | 78 | 70 | 68 | 83 | 83 |

| Solar Heat Gain (G) | 0,68 | 0,58 | 0,39 | 0,33 | 0,68 | 0,68 |

| Sound Insulation Rw (C;Ctr) dB | 36 (-2;-3) | 36 (-2;-3) | 36 (-2;-3) | 36 (-2;-3) | 36 | 39 |

| Properties |

Extra clear Extra thermal Extra light |

Clear Color-neutral glass Ultra thin: > 6,7 mm |

Solar control glass |

Best U-value Extra solar control Commercial buildling |

Heritage glass (light drawn) | Heritage glass (strongly drawn) |

Everything in one convenient overview? Download our brochure

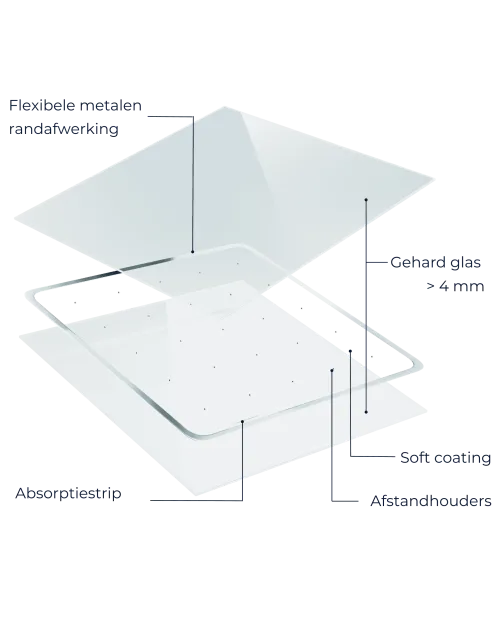

The unique technology behind vacuum glass

Vacuum glass is a unique and advanced product. It consists of two (tempered) glass plates of at least 3 or 4 millimeters thick, with a vacuum cavity of only 0.3 millimeters between them. This results in a total glass thickness from 8.3 millimeters. This vacuum cavity contains spacers, an absorption strip and a very strong edge seal.

- Spacers - distribute the pressure so the glass sheets do not break during the vacuum process.

- Absorption strip - removes residual gases during the vacuum process and keeps the vacuum stable.

- Edge seal - to maintain the vacuum and optimize its lifetime

BENG glass: the best vacuum glass brand in the world

BENG glass is produced by LandVac, the pioneer and global leader in high-performance vacuum glass with a proven track record since 2016. Thanks to a state-of-the-art factory with a capacity of 230,000 m² of vacuum glass per year, deep expertise in toughening furnaces and 429 patents, LandVac operates at a level that other vacuum glass brands simply cannot match.

That's why only at BENGglas do you benefit from this unique blend of advantages:

- The best Insulation value available worldwide: from U=0.35

- Additional sound insulation from 36 dB, rising to 42 dB in laminated versions

- Patented titanium technology - for extra strength and a lifetime of up to 50 years

- European tested vacuum glass by ift Rosenheim (2025) - with a proven track record since 2016

- Up to 7x fewer spacers - than other brands of vacuum glass

- Toughened vacuum glass - injury safe with no risk of thermal breakage (NEN 3569)

- 100% quality control - every window is extensively tested after production

- 20 year warranty

How is vacuum glass different from HR++ and triple glazing?

Vacuum glass is a revolutionary step in the field of (glass) insulation. Vacuum glass is extremely thin insulating glass in which two sheets of glass are separated by a vacuum space. Unlike traditional insulating glass, where noble gas or air is used, a vacuum limits any form of conduction. This allows extremely good sound and heat insulation to be achieved with less material than, for example, HR++ or triple glazing.

This also makes the glass a lot more durable in material use in addition to its high insulation value. These are the main differences:

1. The best insulation value you can get

BENG glass is known worldwide for its exceptional insulation performance. You lose less heat and your living comfort increases noticeably.

- BENG glass: U=0.35

- HR++ glass: U=1.10

- Triple glazing: U=0,70

2. Thin glass that fits into existing frames

Because BENG glass is so compact, it fits into almost any existing window frame. HR++ and triple glass are much thicker and often require new window frames. So with BENG glass, you maintain the appearance of your home or building while getting the best possible insulation.

- BENG glass: 8.3 mm

- HR++ glass: 21 mm

- Triple glazing: 38 mm

3. Extra natural light and spacers

Despite the extremely low U-value, BENG glass lets in up to 15% more natural light than triple glass. There are versions that are extra clear, such as BENGglas Extra Clear, or extra solar control (light tint), such as BENGglasSolar Control. Based on your requirements, we always choose the product that best suits your situation.

Vacuum glass, unlike HR++ or triple glass, has tiny dots in the glass. These are necessary to protect the two panes of glass during the vacuum process and are found in all brands worldwide. In BENG glass, these dots are up to seven times less present than in other brands and finished in non-reflective anthracite. They are always 55 cm apart. This prevents reflection from sunlight and does not interrupt your vision. When you look through the glass they are usually not noticeable, but this varies from person to person. Therefore, always look at a sample before making a choice.

- BENG glass: >83%.

- HR++ glass: >80%.

- Triple glazing: >65%.

4. Constant performance, even at slope angles

With vacuum glass, the insulation value remains the same when the glass is installed at an inclined or horizontal angle. Classic insulating glass then loses much of its performance.

- BENG glass: remains stable

- HR++ glass: up to -60%.

- Triple glazing: up to -40%.

5. Strong noise reduction

BENG glass scores well on all pitches. With laminated glass or special acoustic foils, the attenuation can increase further.

- BENG glass: 36 dB (-2; -3)

- laminated: up to 39 dB

- with acoustic foils: up to 42 dB

- HR++ glass: 31 dB (-1; -4)

- Triple glazing: 33 dB (-2; -6)

HR++ usually comes out in practice between 30 and 37 dB and triple glass around 31 to 37 dB, with low tones in particular being less well attenuated. BENG glass remains stable around 33-34 dB and can increase further in laminated variants.

6. Long and stable service life

The performance of BENG glass remains the same for many years. Whereas HR++ and triple glass slowly decline in U-value over time, vacuum glass remains stable.

- BENG glass: up to 50 years

- HR++ glass: 20-25 years (gradual decline)

- Triple glazing: ± 30 years (gradual decline)

What are the benefits of vacuum glass?

Vacuum glass is no ordinary insulating glass - it is a smart and future-proof solution for sustainable construction. Compared to standard insulation glass, BENG glass offers benefits that directly improve your home as well as help the climate.

- Superior insulation

With a U-value starting at 0.35 W/m²K, BENG glass is two times better than triple glazing (0.70) and three times better than HR++ glass (1.10). This ensures less heat loss, lower heating costs and a comfortable home. - No loss of insulation in slope

Many insulation glasses lose up to 60% of their performance when installed at an angle. BENG glass continues to perform. - Up to twice the lifespan

Whereas traditional glass lasts an average of 25 years, BENG glass lasts up to 50 years. Producing it once means less CO₂ and half a century of benefit. - Strong noise reduction

From 36 dB to 42 dB, well above HR++ (31 dB) and triple glazing (33 dB). As a result, you live more quietly and peacefully. Ideal for homes or properties on busy roads. - More comfort all year round

Cool in summer, warm in winter - without draughts or cold spots. - No condensation on the inside

The unique edge seal completely prevents interior condensation. - Fits into existing window frames

With only 8.3 mm thickness, BENG glass almost always fits into existing window frames. This makes renovations easier and avoids unnecessary use of materials. - A true climate hero

If the entire Netherlands switches to BENG glass, we save up to 4.1 megatons of CO₂ annually - comparable to 170,000 car trips from Amsterdam to Paris.

The production of BENG glass itself will also save 24,000 tons of CO₂ per year, thanks to production using green energy, 30% less material usage than with triple glazing, up to twice the lifespan and high insulation. - A smart investment in the future

A U-value that insulates up to 2x better and that for as much as 50 years. Combine that with an improved energy label and a higher home value and you have your costs back immediately!

What is the cost of vacuum glass?

The price of vacuum glass varies by application. But vacuum glass also helps you save costs on several components:

- new window frames are usually not necessary (unlike HR++)

- twice the lifespan, so fewer replacement costs

- no extra hinges and locks

- a lower energy bill thanks to a stable U-value that remains the same for up to 50 years

- a better energy label and a higher home value

Competitively priced from €295 per m²

BENG glass is deliberately priced low. The recommended retail price starts from €295 per m², excluding VAT, transport and assembly. On top of that come the Dutch subsidies for vacuum glass, which can amount to €46 per m².

What does vacuum glass cost for you?

Fill out the quote form and receive 3 reliable quotes from certified BENG glass installers in your area.

What determines the final price?

- The total number of square meters

- the product type and the choice for extra options such as: laminated or hybrid BENG glass

- Installation included or not

For larger quantities, the price per square meter may be lower. If you choose additional options or installation, the investment is usually higher.

Business order?

Mail us at info@bengproducts.nl.

How can I order vacuum glass?

Simply request a vacuum glass quote and immediately receive 3 quotes from certified BENG glass installers in your area. You fill out the quote form once and within a minute you will have a clear price overview, including professional installation. This way you can compare calmly and know exactly where you stand.

We only work with certified vacuum glass installers who have experience with BENG glass and are familiar with installing vacuum glass. That ensures careful installation and a result you can count on for years to come.

Already working with a regular glass installer? No problem. He or she can contact us directly for coordination and delivery of the glass at info@bengproducts.nl.

If you only need the vacuum glass and you handle the installation yourself, we will deliver the BENG glass directly. For this, simply contact us at info@bengproducts.nl.

Why is vacuum glass such a good investment?

Because you don't just buy glass, but a future-proof solution that really saves money and energy. BENG glass has an insulation value from 0.35 W/m²K - that is 2x better than triple glass (0.70) and even 3x better than HR++ glass (1.1). Less heat loss immediately means lower heating costs. It also means a better energy label and thus a higher home value. The effective payback time is often 0 years.

But that's not all. BENG glass lasts up to 50 years, while standard glass needs to be replaced after 25 years on average. Invest once, and you're set for two generations. That means less maintenance, less replacement, and thus lower overall costs.

The environment also benefits: if the entire Netherlands switches to BENG glass, we save as much as 4.1 megatons of CO₂ annually - comparable to 170,000 car trips from Amsterdam to Paris. Less CO₂ emissions and a lower energy bill: that's what we call an investment that pays for itself.

In short: with BENG glass you invest in sustainability, comfort and financial savings. Smart, right?

What is the insulation value of vacuum glass? The lower the U-value, the better the insulation

The insulation value of glass - expressed as a U-value - indicates how much heat a glass structure loses. The lower the U-value, the better the glass insulates.

Vacuum glass from BENG glass achieves a U-value as low as 0.35. This makes this vacuum glass more than twice as insulating as HR++ glass (U=0.70) and almost three times as good as HR++ glass (U=1.10) - while being much thinner and fitting into existing window frames.

How long does vacuum glass last?

The expected lifetime of vacuum glass is 50 years - with retention of insulation value.

This is considerably longer than traditional insulation glass such as HR++ or HR+++, which usually lasts between 20 and 40 years. The insulation value often decreases due to gas leaks or contamination in the frame.

Vacuum glass is still relatively young, so how do we know it will last this long?

Thanks to reliable laboratory tests. In special test rigs, decades of weather, wind and UV radiation are simulated. Based on this, we can say with confidence: vacuum glass continues to perform for a long time - without compromising on insulation.

Up to 20 years of warranty thanks to unprecedented longevity

At BENG glass, we think ahead. With an expected lifetime of no less than 50 years, we give you up to a 20-year warranty - that's twice as long as HR++ or HR+++ glass.

Our warranty applies to re-supplying your BENG glass window(s) free of charge if it loses its insulating effect within the warranty period. So you can be sure you'll be fine for years to come.

Want to know more?

View the full warranty conditions under ''documentation''.

Will I get a subsidy on vacuum glass?

On vacuum glass you get attractive subsidies in the Netherlands as well as in Belgium. We briefly explain the subsidies below:

Netherlands:

Preserving your home with BENG glass? Then you are eligible for a nice reimbursement through the Investment Subsidy for Sustainable Energy and Energy Saving (ISDE). These are the amounts you can get back:

- €25 per m² if you only replace the glass with BENG glass (report code: KA18780)

- €111 per m² if you also replace your window frames (reporting code: depending on composition)

- €46 per m² when preserving a national monument with BENG glass.

And it gets even more interesting: if you combine the glass with another insulation measure - such as roof or floor insulation - then the subsidy doubles .

Are you unsure whether your home is a national monument? Do the check on RVO.nl

Belgium

Are you having the old glass in your home or building replaced with BENG glass? Then you can make use of the Flemish renovation grant. You will receive as much as €16 per m² back - a nice helping hand in improving sustainability.

This is how to apply for the subsidy:

- Have BENG glass installed by an approved contractor or BENG glass dealer.

- Apply for your subsidy via the Vlaanderen.be online counter

- Use the contractor's installation certificate with your application

Within a few steps it's arranged - and you save immediately.

Frequently asked questions

What is vacuum glass?

Vacuum glass consists of two sheets of glass at least 4 mm thick, with a vacuum cavity of only 0.3 mm between them. Because no air or gas is present, heat and sound transmission is virtually eliminated. An additional heat-reflective coating also blocks heat radiation.

With a total thickness of only 8.3 mm, you thus achieve an insulation performance that is two to three times better than HR++ glass - even when installed at an angle.

Depending on the brand of vacuum glass, the insulation value is usually between 0.35 and 0.70. Only with BENG glass do you benefit from the best possible value as standard: U=0.35.

The sound attenuation is also higher with vacuum glass. Whereas HR++ often stops around 31 dB, vacuum glass starts at a minimum of 30 dB. BENG glass takes this a step further and has a noise reduction from 36 dB. In hybrid variants, this even rises to 41 dB. Ideal for those who want peace and quiet in their homes.

The lifespan is another big advantage. HR++ lasts 20 to 25 years on average, triple glass up to about 30 years, while vacuum glass has a lifespan of up to 50 years.

What is the difference between vacuum glass and regular insulating glass?

Regular insulation glass - such as double glazing, HR++ or triple glazing - consists of two or three panes of glass with a gas-filled cavity. This acts as insulation, but remains more sensitive to heat conduction. As a result, the insulation value is lower(U=0.70-1.10) and the performance decreases as soon as the seal is damaged by weathering or corrosion, for example. The average service life is about 20 to 30 years.

In addition, standard insulation glass is much thicker (from 21 mm). As a result, window frames often need to be modified or replaced. With vacuum glass, this is usually not necessary.

Advantages of vacuum glass

- fits into existing window frames

- Insulation up to three times better than HR++ (depending on the brand)

- lifespan up to 50 years

- no drop in insulation value when inclined

- strong noise reduction

- more comfort: cool in summer, warm in winter

- no condensation on the inside

Why BENG glass is unique

- the highest insulation value in the world: U=0.35

- the best noise reduction: from 36 dB to 41 dB in hybrid versions

- up to seven times fewer spacers than other brands

- standard safety glass (toughened) from 8.3 mm (NEN3569), semi-toughened from 6.7 mm

- produced with patented titanium technology for extra strength, insulating power and service life

- Extra-large glass sizes: 3,450 x 4,150 mm

- independently tested by ift Rosenheim (2024)

- provided with European test reports

- Produced on 100% green energy

- Free of heavy metals

When is vacuum glass interesting?

- Renovation of existing buildings

Due to its thin construction, it often fits directly into existing window frames, preserving the original appearance. - New construction and energy-efficient homes

Vacuum glass helps achieve high insulation standards and ensures a pleasant indoor climate. - Noise reduction

Perfect for homes in urban areas or along busy roads. - Projects with high sustainability or comfort requirements.

Vacuum glass saves more energy than other types of insulating glass and consists of 30% less material than triple glazing. On top of that, BENG glass is produced with green energy and delivers a substantial CO₂ reduction due to its extremely low U-value. Ideal for projects that need to be future-oriented and sustainable.

What are the benefits of vacuum glass?

Vacuum glass is no ordinary insulating glass - it is a smart and future-proof solution for sustainable construction. Compared to standard insulation glass, BENG glass offers benefits that directly improve your home as well as help the climate.

- Superior insulation

With a U-value starting at 0.35 W/m²K, BENG glass is two times better than triple glazing (0.70) and three times better than HR++ glass (1.10). This ensures less heat loss, lower heating costs and a comfortable home. - No loss of insulation in slope

Many insulation glasses lose up to 60% of their performance when installed at an angle. BENG glass continues to perform. - Up to twice the lifespan

Whereas traditional glass lasts an average of 25 years, BENG glass lasts up to 50 years. Producing it once means less CO₂ and half a century of benefit. - Strong noise reduction

From 36 dB to 42 dB, well above HR++ (31 dB) and triple glazing (33 dB). As a result, you live more quietly and peacefully. Ideal for homes or properties on busy roads. - More comfort all year round

Cool in summer, warm in winter - without draughts or cold spots. - No condensation on the inside

The unique edge seal completely prevents interior condensation. - Fits into existing window frames

With only 8.3 mm thickness, BENG glass almost always fits into existing window frames. This makes renovations easier and avoids unnecessary use of materials. - A true climate hero

If the entire Netherlands switches to BENG glass, we save up to 4.1 megatons of CO₂ annually - comparable to 170,000 car trips from Amsterdam to Paris.

The production of BENG glass itself will also save 24,000 tons of CO₂ per year, thanks to production using green energy, 30% less material usage than with triple glazing, up to twice the lifespan and high insulation. - A smart investment in the future

A U-value that insulates up to 2x better and that for as much as 50 years. Combine that with an improved energy label and a higher home value and you have your costs back immediately!

What are the differences between vacuum glass (BENG glass), triple glass and HR++ glass?

Vacuum glass works in a different way than traditional insulating glass. Whereas HR++ and triple glass use air or gas between the panes of glass, with BENG glass the cavity is completely evacuated. This provides performance that simply cannot be achieved with regular insulation glass. Here are the main differences:

1. By far the best insulation value available

BENG glass offers the best insulation value worldwide. You save more heat and increase comfort in your home.

- BENG glass: U=0.35

- HR++ glass: U=1.10

- Triple glazing: U=0,70

2. Fits into existing window frames, preserving authentic appearance

BENG glass is extremely thin and almost always fits into existing window frames. HR++ and triple glass are much thicker and often require replacement of your window frames. So with BENG glass, you preserve the appearance of your building while enjoying impressive insulation performance:

- BENG glass: 6.7 mm

- HR++ glass: 21 mm

- Triple glazing: 38 mm

3. More daylight and extra clear glass (LTA).

Because BENG glass is so thin, the glass remains beautifully clear. Despite its extremely good insulation value, it lets in up to 15% more daylight than triple glazing, for example. There are variants that are extra clear or sunproof, depending on your needs.

- BENG glass: >83%.

- HR++ glass: >80%.

- Triple glazing: >65%.

4. Stable performance with horizontal installation

With BENG glass, the insulation value always remains stable even when the glass is placed at a horizontal inclination. With traditional insulation glass, the performance drops significantly.

- BENG glass: remains stable

- HR++ glass: up to -60%.

- Triple glazing: up to -40%.

5. Maximum noise reduction

BENG glass delivers strong performance at all pitches. With a laminated version or acoustic foils, the attenuation can increase even further.

- BENG glass: 36 dB (-2; -3). Laminated up to 39 dB, with acoustic foils up to 41 dB.

- HR++ glass: 31 dB (-1; -4)

- Triple glazing: 33 dB (-2; -6)

Based on the above data, HR++ usually attenuates between 30 and 37 dB and triple glass between 31 and 27 dB, with low tones in particular being less well attenuated. BENG glass remains stable around 34-33 dB and therefore performs broadly. In laminated versions or with additional acoustic foils, this BENG glass increases further.

6. Lifetime

The performance of BENG glass remains at the same level for decades, without relapse.

- BENG glass: up to 50 years stable

- HR++ glass: 20-25 years, with gradual decline in U-value

- Triple glazing: ± 30 years, with gradual decline in U-value

How long does vacuum glass last?

Vacuum glass not only lasts longer than traditional insulating glass, it also continues to perform as if it had just been installed. With standard insulation glass, the U-value slowly decreases after a few years. With BENG glass, it remains stable - for years.

How do we know for sure? In the lab, conditions of 25 years of use are simulated. Afterwards, the U-value was still exactly the same. Therefore, we confidently guarantee a 25-year service life, with an expected total service life of 50 years.

And with a 20-year warranty, BENG glass is well above the market standard - that's 10 years more than usual in the glass world.

Will vacuum glass fit in my window frame?

Whether you have wooden or aluminum window frames, BENG glass's vacuum glass fits almost always. Thanks to its clever construction and ultra-thin thickness of only 6.7 mm, our glass is designed to fit into existing window frames. That means: no unnecessary renovations, no expensive new window frames and no hassle.

And the best part? You retain the authentic look of your home. Perfect for monumental buildings, homes from the 1930s or any home where character plays a role. This way you combine top insulation with style and atmosphere.

Did you know.

If necessary, we can even thicken the glass (hybrid vacuum glass) or laminate it so that it fits any profile - completely customized. Easy, isn't it?

We then place an extra cavity and/or pane against the vacuum glass package.

One of our regular partners in the field of aluminum window frames is Smits Kozijnen. Want to know more about our partnerships or curious about reliable installers in your area? Then be sure to take a look at the partner page.

What does vacuum glass cost?

The price of vacuum glass varies by brand and application. Count on about 285 to 400 euros per square meter (sales advisory price excluding VAT, transportation and installation). More important, however, is what it will save you in total.

After all, with vacuum glass you save on:

- new window frames

- heavy (and expensive) hinges and locks

- your energy bill

- replacement costs (no 20-30 years, but a life span up to approximately 50 years)

- And you benefit from a better energy label.

On top of that, the value of your home increases immediately.

The recommended retail price of BENG glass is 285 euros per square meter, excluding installation, transport and VAT. The final price depends on your situation. If you order many square meters, the price per square meter may be lower. If you choose laminated or hybrid BENG glass and want a price including installation, then the investment will most likely be higher.

Want to know exactly what BENG glass will cost in your case?

Then fill out our quote form and receive 3 reliable quotes from certified BENG glass installers in your area.

Want to order for business? Then email us at info@bengproducts.nl.

How do I request a vacuum glass quote?

At BENGglas, we understand that you don't want to spend a long time getting an honest price comparison.

By filling out our quote form , you will immediately receive three quotes from three authorized dealers in your area. These quotes include both delivery and installation of the vacuum glass.

Would you still prefer to decide yourself from whom you get a quote? That's easy, too.

Useour Dealer Finder byentering your zip code. You will then immediately get an overview of BENG glass dealers in your area, including their contact details and their own page with a quotation form. If desired, additional work, such as painting, can also be included. In this way, our dealers always offer a complete total solution.

All BENG glass dealers have sample windows, so you can view the glass and make an informed choice. You are also welcome to visit our showroom by appointment to experience the possibilities in person.

Is there no dealer near you? Then ask your local glazier to contact BENGglas at info@bengproducts.nl.

Why are there dots (spacers) in vacuum glass?

If you've ever looked closely at vacuum glass, you may see them: little dots between the two sheets of glass. We call those spacers.

Spacers are tiny supports in the vacuum cavity (the space between the glass panes). They keep the glass layers from being pulled together when the air between them is removed. Without these supports, the glass could literally break due to the pressure.

In BENG glass, the spacers are:

- Placedonly every 55 mm - which is much less than other brands of vacuum glass.

- Anthracite in color, making them much less noticeable than clear or silver variants that reflect light.

Benefit for you?

A nice, calm and undisturbed view through your windows, without distracting reflections or a "grid"-like effect you sometimes see with other vacuum glass types.

Note, however, that during condensation season, you may see a sort of "dam" pattern on the glass. This means that condensation forms everywhere on the glass except around the spacers. That's because these little supports allow heat to pass through a little better, so moisture is less likely to set on the outside.

Fortunately, there are special anti-condensation coatings available that can help reduce this effect, keeping your windows looking nice longer - even in humid conditions.

What is the history of vacuum glass?

Vacuum glass was first patented in Germany in 1913. Yet it was not until 1996 that the first commercial products appeared - originating in Japan and South Korea. These early versions were still of limited use and not suitable for broader applications in construction.

The real breakthrough didn't come until 2016, when LandGlass became the first in the world to launch a fully tempered, tested and certified vacuum glass: LandVac®. Since then, the technology has continued to develop at lightning speed - resulting in a high-quality, reliable and durable titanium vacuum glass.

This was followed in 2019 by Fineo (from AGC), intended for lighter applications. But those opting for maximum performance in terms of insulation, safety and longevity will end up with LandVac.

BENGglas is the exclusive importer of LandVac in the Netherlands, Belgium and several other European countries.

Is there a CE mark for vacuum glass?

There is currently no harmonized European standard that makes vacuum glass mandatorily covered by CE marking. View the full explanation and statement from TÜV Rheinland here . Therefore, BENG glass does not (yet) have a CE mark. But that doesn't mean you have to doubt its quality. BENG glass has, however, been extensively tested and certified.

Since its market introduction in 2016 (through Landvac), BENGglas has proven itself to be a reliable and innovative product, with no fewer than 429 patents!

Moreover, BENGglas has important quality statements and reports, such as:

- Independent and European insulation value reports by ift Rosenheim and TÜV Rheinland

- Toughness reports for safety and sturdiness

- A BCRG declaration, an independent seal of approval for quality and safety

- CIC Green Product Certification for environmental compatibility

- Noise value reports for optimum sound insulation from ift Rosenheim

- Rohs report stating that BENG glass is free of heavy metals

All these certifications ensure that with BENG glass you are choosing a product that meets high quality standards, even though there is no official CE mark.

How does vacuum glass retain its insulation value (u-value)?

Up to 50 years of service life thanks to BENG glass's titanium technology

Whereas traditional insulation glass loses its performance over time due to leaking seals, BENG glass remains completely airtight for years. This is due to the patented titanium edge seal, in which the glass sheets are fused at the edges and hermetically sealed. As a result, BENG glass lasts up to two times longer than standard insulating glass: up to 50 years.

Why titanium is so powerful

- Much less heat conduction due to titanium spacers (approximately 70%)

- Longer life thanks to a titanium absorption strip that keeps the vacuum stable

- Up to 40% stronger, with 90% less stress build-up

- Excellent protection against corrosion and wear

In short: titanium gives BENG glass maximum insulation strength as well as an impressive lifespan.

What glass thickness do I need for my vacuum glass project?

BENG glass comes in different thicknesses, so we always have the perfect match for your windows. This prevents distortion, warping and other hassles .

The larger the glass, the thicker the construction. Glass thickness is determined based on the area of a single pane of glass:

- 6.7 to 8.3 mm: up to 3 m²

- 10.3 mm: from 3 to 4 m²

- 12.3 mm: from 4 to 4.8 m²

- 16.3 mm: from 4.8 m²

Is BENG glass too thin for your window frames? No problem!

BENG glass is ultra-thin, but if your frames are a bit wider than 16.3 mm, we can also thicken (BENG glass Hybrid) or laminate the glass. This way it even fits perfectly into wider profiles, without having to replace your frames.

Not sure what thickness best suits your windows? No stress, we are happy to help you with a personal advice that fits your situation!

Why is vacuum glass the gamechanger that will help solve the climate crisis?

The climate crisis calls for radically different solutions. Yet the biggest energy leak in buildings often remains invisible: the glass. BENG glass is not just insulation glass, but a pioneering technology with a U-value starting at 0.35 W/m²K - almost twice as good as triple glazing (0.70), three times better than HR++ (1.10) and better than any other brand of vacuum glass. Moreover, BENG glass lasts an average of 50 years, twice as long as traditional glass, and is produced using 30% less material compared to HR++ glass.

This means concretely:

- Only one production cycle every 50 years, with 50% less raw materials and transportation

- Structurally 50% less CO₂ emissions during production

- Up to 30% less glass volume and lighter weight, saving building materials and assembly time

- Suitable for any existing frame thanks to its revolutionary thickness of only 6.7 mm

BENG glass combines enormous energy savings with a drastic reduction in environmental impact - an innovation that is not only smarter, but also indispensable in the energy transition.

Want to know more? Read more here .

Which vents are suitable for vacuum glass?

Ventilation grilles allow fresh air into your home even when your windows and doors are closed. They help wick away moisture, ensuring a healthy indoor environment. Especially with well-insulated glass such as BENG glass's vacuum glass, good ventilation is especially important, as otherwise the house becomes too "dense" and moisture problems can occur; insulation and ventilation often go hand in hand.

The good news?

There is a ventilation grid that works perfectly with BENG glass! Duco has developed the GlasVent ZR AK (+) type, specially designed to work well with vacuum glass. So you enjoy optimal insulation and fresh air.

Want to know more? Take a look at our Duco partner page.

How do you recognize vacuum glass and BENG glass?

Vacuum glass works completely differently than traditional double glazing or HR++ glass. Because the cavity is vacuum, the glass performs much better ánd looks different up close. Below are the characteristics by which you can recognize vacuum glass - and specifically BENG glass.

1. The unique combination of glass thickness and insulation value

Vacuum glass immediately stands out because of the ratio between thickness and performance. With a glass construction starting at 6.7 mm, you can achieve an insulation value of U=0.35 to 0.70. With regular insulation glass, this is impossible.

With BENG glass, you benefit from the highest insulation values within all vacuum glass brands: U=0.35 to 0.50, depending on the type chosen. So you preserve your window frames while enjoying the best insulation value worldwide.

2. Absorption strips

On the longest side of the vacuum glass is an absorption strip that removes moisture from the cavity during the vacuum process.

After installation, if the installation instructions have been followed, this strip disappears completely behind the glass slats.

Depending on the pane length, BENG glass has one or two absorption strips. More details can be found in our technical drawings.

3. The spacers (the small dots in the glass).

Each brand of vacuum glass has small dots in the glass: the spacers (also called microspacers or micropillars).

The distance between these dots, as well as the color, varies among manufacturers.

- BENG glass: spacers every 55 mm.

- Other brands: often 25-40 mm

With BENG glass, the spacers are always in non-reflective antractite. This prevents reflective sunlight, allowing the spacers to actually light up. All BENGglas dealers have product samples, so you can see the spacers for yourself.

4. Edge seal

A colored edge seal is a clear identifying feature of vacuum glass. You can often tell immediately by the color which brand it is.

With BENG glass, you can recognize the edge seal by:

- Nicely rounded corners - important for maintaining vacuum

- Edge height of approx. 9 mm all around

- Total visible height of approx. 13-14 mm including absorption strip

- Specific colors: white, dark red or light yellow

(BENG glass never has green, dark yellow or other different colors).

5. Hardly any chance of thermal breakage

Because BENG glass is tempered as standard, the chance of thermal breakage is very low.

Only in exceptional cases can it still happen.

How do you recognize thermal breakage?

- The crack always starts at the edge of the glass

- Runs straight to the warmest/coolest part

- Then it bends and continues in a jagged fashion

Are you unsure if your window has a thermal break? Feel free to contact us, we'd be happy to take a look with you.

Want to be sure if you have BENG glass?

Contact us or check this page for more information. We'll be happy to help you further.

Is tempered vacuum glass safer than untoughened vacuum glass?

Yes. Toughened vacuum glass is significantly safer than untoughened vacuum glass. The toughening process makes the glass up to five times stronger, able to withstand large temperature differences and better able to withstand pressure loads.

When broken, tempered vacuum glass breaks into small, blunt grains, minimizing the risk of injury. Unhardened vacuum glass, on the other hand, breaks into sharp shards and offers no injury safety.

This is why BENGglas always works with toughened vacuum glass that complies with NEN3569. This ensures maximum safety, stability and durability.

How thick is vacuum glass?

Vacuum glass varies in thickness depending on the brand you purchase. This can be as low as 6.7 millimeters for untoughened vacuum glass, but often the minimum glass thickness starts at 6.7 millimeters. Depending on the window area, this can go up to a minimum glass thickness of 16.3 millimeters.

The minimum glass thickness in BENG glass:

BENG glass's vacuum glass consists of two sheets 3, 4, 5 or 6 mm thick with a vacuum space of only 0.3 mm between them. This brings the minimum glass thickness to 6.7 millimeters (semi-tempered) or 8.3 millimeters for tempered vacuum glass.

Depending on the desired window area, the minimum glass thickness is determined.

The larger the pane, the thicker the structure must be to prevent deformation or warping:

- up to 3 m²: 6.7 - 8.3 mm

- from 3 to 4 m²: 10.3 mm

- from 4 to 4.8 m²: 12.3 mm

- from 4.8 m²: 16.3 mm

Since BENG glass is available up to 4,120 mm (where other vacuum glass brands can only produce up to 2,500 mm), it is possible that the pane thickness will be 16.3 mm.

Do you prefer thicker vacuum glass anyway?

BENG glass can be thickened or laminated. This means that either an extra pane or an extra cavity with pane is placed against the vacuum glass package. This increases the total thickness. Depending on the desired final thickness, we can fully customize the composition.

This way you are always assured that you can keep your window frames.

Not sure what thickness best suits your windows? We would be happy to help you! Be sure to contact us.

What is tempered vacuum glass?

Tempered vacuum glass is vacuum glass in which both sheets of glass are tempered. This means that the glass is first heated to a very high temperature and then cooled at lightning speed. This process creates a permanent, internal stress that makes the glass up to five times stronger than ordinary, untoughened glass.

Whereas untoughened vacuum glass is more fragile and susceptible to breakage, toughened vacuum glass, like BENG glass, can handle large loads, pressure differences and temperature changes effortlessly. This is why toughened vacuum glass is also called safety glass (injury-safe glass).

Why is toughened vacuum glass so much stronger?

The following happens during the toughening process:

- The glass is heated evenly to about 650 °C

- The surface is then cooled very quickly

- The outer layers tighten

- The inner core cools slowly and remains under tension

That combination creates a glass structure that:

- is 5× stronger

- Is much more resistant to impact and pressure

- tolerates temperature variations without breaking

- remains stable and retains its shape - essential for vacuum glass

This virtually eliminates thermal breakage - glass breakage due to temperature stresses - in BENG glass.

How does tempered vacuum glass break (injury safe)?

If tempered vacuum glass does break, it does not fall into sharp, dangerous shards.

The glass disintegrates into small pieces, minimizing the risk of cuts.

Why do some brands still choose untoughened vacuum glass?

Unhardened vacuum glass is easier to produce, but :

- is more susceptible to thermal breakage

- is not injury-safe

- can handle less pressure

- is less suitable for large windows

So tempered vacuum glass is a higher quality grade.

At BENG glass you always get toughened vacuum glass

Many brands still supply untoughened vacuum glass.

BENG glass never does. With us, toughened, injury-safe vacuum glass is the standard - at no extra charge.

That means:

- more safety

- more stability

- higher durability

- better performance

- fewer risks

What exactly is laminated vacuum glass?

Laminated BENG glass offers tremendous possibilities: you can choose from three types of films (EVA, PVB or SentryGlas Plus) and a virtually unlimited range of counter glasses.

All film types ensure that no shards will come loose if broken. But it doesn't stop there - you benefit from many more smart advantages. Each film type has unique properties, giving the window - in addition to the superior insulation value of BENG glass - many extras, such as:

- fall-through safety - well safe at height, for all building functions

- Break-in retardation -not easy to get through

- extra sound insulation - from -36 dB to -39 dB or more, audibly quieter

- Better UV protection - your furniture stays nice longer

- colors and patterned glass - your window will completely change appearance

How you want to put together your laminated window is completely up to you. Think of patterned glass for a unique look, or additional films for maximum safety. Let us know what you are looking for - and we will be happy to think along with you.

When do I choose laminated vacuum glass?

Laminated vacuum glass is used in places where extra safety, soundproofing or structural strength is important in addition to insulation. Think of glass at height, roof glazing or in situations where you have high noise levels.

In many cases it is even mandatory, for example if there is a risk of falling through or in roofs. The film between the layers of glass ensures that the glass does not break into sharp shards when broken - making it safer and more comfortable in everyday use.

- Facades

As standard, BENG glass is injury-resistant on both sides: when broken, it disintegrates into small grains. In facades with height differences, laminated glass is mandatory, avoiding the risk of falling through.

Thanks to the built-in UV filter in PVB film, furniture and floors are less likely to discolor. - Roof glazing

With overhead glass, safety is not a choice but a requirement. Laminated vacuum glass is the standard here: when broken, it stays together and prevents shards from falling down. Daylight comes in as normal, while the UV filter prevents discoloration of floors and furniture. - Living past crowds? More quiet indoors?

Noise from (air) traffic, neighbors or a schoolyard can be distracting. With acoustic laminated glass, the noise level goes down noticeably. A special interlayer in the glass absorbs some of the sound vibrations - ideal for bedrooms, work spaces or simply more peace and quiet in the living room.

Will laminated vacuum glass fit into my existing window frames?

In most cases, yes. Laminated BENG glass is available from as little as 13.06 mm thick, which is thinner than triple glazing. Having doubts about whether it will fit? Then we can look with you or engage an authorized dealer in your area.

What is the G-value (of vacuum glass)?

The G-value (solar factor) indicates how much solar heat comes in through the glass. So: how much free heat from the sun do you actually feel inside?

Good to know: whatever G-value you choose, with BENG glass you are always assured of excellent insulation - much better than HR++ or triple glazing.

And it shows: your house loses less heat, stays warmer for longer and you don't have to heat as much. This makes a big difference to your energy bill, especially in the winter or in older homes.

What does differ is how much solar heat and daylight you let in.

- Higher G-value → more solar heat inside. Great for bright rooms or cold facades.

- Lower G-value → more solar heat blocked. Ideal for lots of glass, warm rooms or summer sun.

You choose what suits you

BENG glass comes in several variants, each with its own balance of light, heat and solar control.

Do you want extra daylight? More sun protection? Or just a little of both? You decide what's important - and whatever you choose:

- it simply fits into your existing window frames

- It is slim, light and super insulating

- it contributes to a more comfortable indoor climate

Below are the types that BENG glass offers and them G-values:

- BENGglas® Extra clear: 0.68

- BENGglas® Single Coated: 0.58

- BENGglas® Double Coated: 0.39

- BENGglas® Triple Coated: 0.33

- BENGglas® Solar Control: 0.29

- BENGglas® Monu: 0.68

- BENGglas® Monu Restover: 0.68

Looking for a different G-value? Even then we'd be happy to think with you. Please contact us to inquire about the possibilities.

What are the advantages of the titanium in the vacuum glass?

Only at BENGglas do you get titanium vacuum glass from LandVac - one of the many unique aspects that set BENGglas apart.

With it, you'll immediately enjoy powerful benefits:

- Titanium spacers reduce heat conduction by as much as 70%

- Titanium absortion strips extend product lifetime

- Flexible edge sealing reduces stresses by 90% and increases bending strength by 40%

If you choose titanium vacuum glass from BENGglass, you are choosing longer life, maximum strength and superior insulation!

BENGglas Extra Clear

BENGglas Extra Clear is the clearest product in our range—almost as transparent as single glazing, yet with an impressive U‑value of 0.50. Ideal for anyone looking to maximize energy savings while enjoying extra natural daylight and free solar heat

- Top insulation (U=0.50)

- Fits in the existing frames

- Extra clear vacuum glass

- Extra light and solar heat (LTA=83, G=0.68)

- U-value tested by IFT Rosenheim (2025)

BENG Glass Single Coated

BENG glass Single Coated combines the color-neutral appearance of HR++ glass with an insulation value of up to 0.40 (U). With a glass thickness of only 6.7 mm, the U-value is 0.50. Perfect for slim frames and monumental buildings.

- Maximum insulation (U=0.40 - 0.50)

- Fits into existing window frames

- Ultra slim: starting at 6.7 mm (U=0.50)

- Color neutral vacuum glass

- Natural light (LTA=78%)

- U-value tested by IFT Rosenheim (2025)

BENGglas Double Coated

BENGglas Double Coated keeps the heat inside with the high insulation value of 0.40 (U). At the same time, a smart solar control coating ensures that the sun's heat stays outside. This way, you always enjoy a cool and comfortable home — and an energy bill that remains low, even on the hottest and coldest days.

- Solar control glass (G=0.39)

- Maximum insulation (U=0.40)

- Fits in the existing frames

- U-value tested by IFT Rosenheim (2025)

BENGglas Triple Coated

BENGglas Triple Coated offers maximum sun protection and the best insulation value in the world: U=0.35! For those who want maximum energy efficiency and sun protection in commercial construction.

- The best insulation value worldwide (U=0.35)

- Highly sun-shielding glass (G=0.33)

- Fits in the existing frames

- U-value tested by IFT Rosenheim (2025)

BENGglas Monu

BENGglas Monu combines extra clear glass with the insulation power of vacuum glass (U=0.50). Thanks to the small thickness of only 8.3 mm and the subtly wavy surface, it is the solution for monuments where the original frames must be preserved.

- Top insulation (U=0.50)

- Extra clear vacuum glass

- Extra light and solar warmth (LTA=83, G=0.68)

- Fits in the existing frames

- The best choice for monumental renovations

- U-value tested by IFT Rosenheim (2025)

BENGglas Monu Restover

BENGglas Monu Restover combines monument glass (Restover) with the insulating power of vacuum glass (U=0.50). The characteristic strong curvature in monument glass retains the authentic appearance that is so typical of historic buildings. For the first time, there is a glass solution that preserves heritage sustainably.

- Top insulation (U=0.50)

- Extra clear vacuum glass

- For extra daylight and solar warmth (LTA=83%, G=0.68)

- Laminated glass: 13.06 mm

- Monument glass: strongly wavy surface (Restover glass)

- U-value tested by IFT Rosenheim (2025)

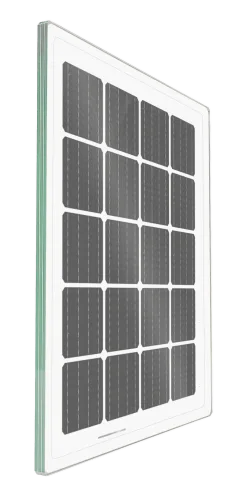

BENG Glass Sun

With BENGglas SUN, you not only save on your energy costs thanks to the extremely low U-value of 0.50 - you also generate your own energy! Thanks to the integrated solar cells, this glass is ideal for facades and roof glazing in sunny areas. Please note: only to be ordered from 50 m² in repeating sizes.

- Top insulation (U=0.50)

- Energy generation (Up to 140 Wp/m²)

- No degradation of U-value when installed horizontally

- Light in weight and slim (> 14 mm)

- U-value tested by IFT Rosenheim (2025)

- Project construction: from 50 m²

BENGglas Solar Control

BENGglas Solar Control offers the best sun protection within the BENGglas range – with an impressively low G-value of 0.29. Ideal for commercial buildings where you want to keep solar heat out and achieve maximum energy efficiency.

- Top insulation (U=0.50)

- Maximum sun protection (G=0.29)

- Fits in the existing frames

- U-value tested by TÜV Rheinland (2025)

BENGglas Pyrovac® EW 30-1

BENGglas Pyrovac® EW30-1 glass is a fire-resistant vacuum glass with a U-value of 0.40 and a total glass thickness of only 15 mm. Thanks to its EW30-1 rating, the glass provides 30 minutes of protection against fire and smoke while significantly reducing heat radiation on the non-fire side.

- Maximum insulation (U=0.40)

- 2-sided damage-resistant (EN 3569) and fall-through resistant glass (EN 2608)

- Rated for fire resistance: EW30, 1-sided fire resistant, UV stable, impact resistance class 1B1

- Glass thickness: 15 mm

- Fully customizable

Find a certified installer

BENGglas has an extensive network of over 150 certified installers across Europe, specializing in vacuum glass installations. This way, you’re always assured of a professional close to home! Want to get the best deal easily? Fill out our quote form and receive three competitive offers from the three nearest BENGglas dealers in your area!

References

Are you curious about where vacuum glass is already being used? Check out our references and discover how BENG glass is being used in all kinds of projects - from listed buildings and protected heritage sites to sustainable new construction, canal houses and sleek offices.

In this way, we are helping window by window to create energy-efficient buildings with fewer CO₂ emissions.

BENGglas in ‘The Art of Living’ with the sustainability of a 100-year-old building

Sustainability of modern office building